| |

|

Knifings Taint an Ancient Craft |

|

Uyghur Craftsmen have Elevated

Knife-making to a High Art, and their Ornate Knives are Prized |

|

Here on the fertile edge of the Taklimakan Desert,

people have long believed that placing a knife on their bedside keeps

away bad dreams. On a baby's seventh day of life, it's tradition for

parents to briefly slip a blade under the sleeping infant's head to

guarantee a long and healthy life. |

By dusty roadsides, farmers with long white beards unsheathe their

blades to slice open juicy green melons, selling sweet wedges for 15

cents. In open-air markets, butchers slaughter sheep, cattle and even

camels in accordance with Muslim practice, skinning the hides and then

swinging cleavers to parcel the carcasses into cuts of meat.

For the ethnic Uighurs who dominate this rural region in far western

China, perhaps nothing is more essential — as tool and talisman — than a

knife. |

|

Traditional Uyghur Knife Dance |

|

Over the centuries, Uighur craftsmen have elevated knife-making to a

high art, fashioning small folding Qelemturachs and larger

Pichaqs one by one in scores of small factories and workshops across

Xinjiang Province. The most expensive and ornate boast silver

blades and handles crisscrossed with intricate inlays of iridescent

shell, stone, bone and other materials, often in geometric patterns with

diamond, circle or even heart motifs. The craftsman's name and hometown

are typically inscribed on the blade, in flowing Uighur script and

sometimes Chinese characters as well.

But in the wake of a string of deadly clashes and terrorist attacks,

including a mass slashing, that Chinese authorities have blamed on

Uighur separatists and religious extremists, the handcrafted knives have

taken on a deadly cast.

The violence has set back the once-thriving tourist trade to the

south of Xinjiang province, and remaining visitors may think twice about

the symbolism of giving anyone a Uighur knife as a gift these days. For

the few sightseers who still want them, confusion over restrictions on

mailing knives or even taking them in check-in airline baggage has

further damped the trade. |

| On a recent weekday, the region's knife-making capital, Yengisar,

resembled nothing so much as a ghost town. Blade-shaped signs 30 feet

tall stood forlornly above ample parking lots designed for tour buses,

and colorful flags flapped in the wind, beckoning customers. |

|

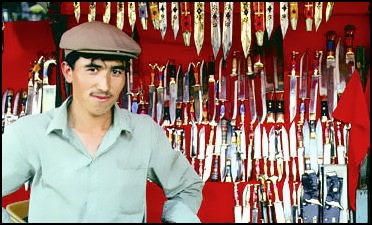

Grand Bazaar - Uyghur Knife Seller

in Urumqi, Xinjiang |

Not only were there no shoppers, but no shops were open. The local

workshops were shuttered as well.

Finally, a policeman happened by and told the neighborhood mini-mart

clerk he wanted to buy an animal-bone comb from the knife shop next

door. The clerk called the owner, who hustled over to throw up his metal

security door and make whatever sale he could.

"Business is bad this year; there are no tourists," the salesman said as

the officer picked out his comb and a few other shoppers wandered in,

browsing the display cases stuffed with knives for every budget, from $5

pocket knives less than 2 inches long to kitchen cleavers and decorative

silver blades with deer horn handles.

Exactly why the entire strip of dozens of shops and small factories was

shut down was unclear. One local said the craftsmen had simply gone off

for 10 days to pick cotton in fields nearby; September is peak harvest

season.But people here are skittish, and no one wants to share their

name with a journalist. Another shop owner said proprietors had been

ordered to close for a week — by exactly whom he didn't specify —

because the provincial capital, Urumqi, a full 700 miles to the

northeast, was hosting a high-profile international trade expo that

week. |

|

|

|

|

Famous Uighur Knives made in Southern Xinjiang |

Uyghur Silver Knives, Swords, Shield & Armor |

Though the notion that authorities might extend security precautions

such a distance may sound far-fetched, China has strict rules on

weaponry. Firearms are tightly controlled and hard to obtain; all but

the smallest knives are supposed to be registered with police upon

purchase.

China has periodically clamped down on knife sales around major national

events. Ahead of the November 2012 ceremony at which Xi Jinping was

elevated to the Communist Party's top post, for example, supermarkets

across Beijing were ordered to stop sales of even small paring knives.

Since then, a series of deadly attacks has set the nation on edge and

given Uighur knives an ominous taint, though it's unclear in many cases

whether the assailants used Uighur knives or mass-produced ones.

In March, black-clad assailants went on a rampage in front of a train

station in the Yunnan province town of Kunming, using large knives to

hack 29 people to death and injuring more than 140. The March attack

prompted authorities to introduce a host of tighter security measures

nationwide. Cops who previously patrolled without guns have been given

firearms. Airport security screeners in Xinjiang now wave their wands

even under the soles of passengers' bare feet. New heavy traffic

dividers have been installed in Beijing's Tiananmen Square. Checkpoints

are common in southern Xinjiang, and in some areas of the province, the

Internet and text-messaging services have been disabled.In July, the

imam of the main mosque in southern Xinjiang's largest city, Kashgar,

was stabbed to death just outside the holy site in broad daylight.

Authorities said the assailants of the imam, who had strong ties to the

Communist Party, were Uighur men in their late teens and early 20s who

were influenced by "extremist" videos and teachings at unauthorized

mosques. |

|

|

|

|

Assorted Uyghur Knifes |

Uyghur Daggers |

An expatriate who recently tried to buy a knife at two supermarkets

in Beijing was told by clerks that they no longer stocked them.

Eventually, the foreigner found a small selection at a specialty kitchen

shop, though concealed behind the counter.

The Uighur craft of knife-making is often passed from father to son.

Down the road from Yengisar, at a dusty rest stop baking in the sun, one

small knife stand was open, and outside, the owner's wife watched their

toddler run around, naked except for a T-shirt.

A drill, grinding equipment and other tools sat in a heap at the front

door of the shop. No customers were browsing the exquisite wares,

everything from plain $10 cleavers to a $500 silver blade with a

decorative inlaid handle that takes one craftsman 15 days to produce.

Asked whether he planned to pass the trade on to his boy, the young

owner just sighed and said, "I have no idea."

Near the village of Kezile, a huge blue-and-yellow knife-shaped sign

greeted motorists pulling in to refuel their vehicles and stuff

themselves with lamb kebabs and noodles at the Brothers Fast Food halal

restaurant. The knife shop next to the eatery was tightly locked up.

Blue signs affixed to the front of the building warned: "Religious

Activity in Public Spaces Is Strictly Prohibited." Another, smaller

green sign detailed rewards up to $8,500 for tipsters who inform police

about "terrorist activities." No one in the area seemed to know when the

shop had shut, or when it might reopen. Six policemen sat under a

canopy, keeping tabs.

A few days later, back in Yengisar, some knife shops had reopened. One

proprietor got lucky when a group of Russian motorcyclists and a busload

of tourists who had driven all the way from Shanghai on China's eastern

coast rolled up. Transporting knives back home would be no problem for

them.

"I didn't know anything about these knives until our guide told us,"

said Gennady Kopylov, 37, of Moscow, who bought a large kitchen knife

for about $50. "I guess some Chinese might be scared now, you know, the

Muslim thing, but these knives are great. And it's no problem to take

them back on the bike." |

|

|

|

|

Uyghur Shop Keeper and Knife Ware |

|

The Knifemakers' Guild traces it's early beginning to February 1970

when a gentleman named A.G. Russell secured tables at the Sahara Gun

Show in Las Vegas, Nevada, and invited several knifemakers to display

knives there. The show proved profitable in many ways, and the

knifemakers parted, eager to get together again. |

Later that year, eleven knifemakers met in Tulsa, Oklahoma to form

the Knifemakers' Guild: John Applebaugh, Walter "Blackie" Collins, John

Nelson Cooper, Dan Dennehy, T.M. Dowell, Chubby Hueske, Jon Kirk, R.W.

Loveless, John Owens, Jim Pugh, and G.W. Stone. R.W. Loveless was

elected Secretary for a year, and A.G Russell was made Honorary

President.

The purposes of the Guild were, and continue to be: to promote custom

knives and knifemakers, to assist the knifemaker technically, to

encourage ethical and professional business conduct, and to sponsor an

annual business meeting and knife show.

Today the Knifemakers' Guild has over 300 members from the United States

and several foreign countries. Members meet once a year to conduct Guild

business, elect officers, and display their work at the annual show.

Thousands of collectors, investors, and sportsmen from around the world

attend the Knifemakers' Guild Show each year to view and purchase

quality, handmade knives and to meet their favorite artists and

craftsmen.

Knifemakers' Guild

P.O. Box 1251

New Port Richey, FL 34656-1251 |

|

|

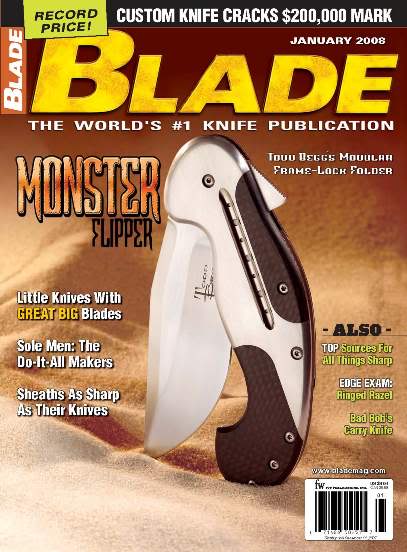

Home of the Best Knifemakers in the

World!

Blade Magazine

A complete guide for knifemakers, collectors and knife

enthusiasts EDITORIAL REVIEW

Blade magazine is an entertaining and instructive magazine for knife

enthusiasts. It contains custom knives, as well as production knives,

new and old. Knife makers as well as knife collectors and aficionados

enjoy this publication because it includes the latest news on knives,

knife making, and the people who make the knives. Feature articles

examine the art of making knives, and call to the light new knife making

techniques and processes from the professionals. These informative

articles serve to educate knife makers on new procedures in making high

quality knives. Other features actually point the spotlight on the maker

himself, giving readers an inside look at the creative mind behind the

knife.

Other articles focus on the testing of knives in the field. These prove

invaluable for those seeking to purchase a new knife for a specific

purpose. The question and answer section of Blade magazine provides

readers with a chance to get their knife related questions answered by

an expert. The articles are well written and insightful, and the

magazine also includes some high quality photos, as well as many black

and whites. Information regarding knife shows across the country is also

published in this magazine. Blade magazine is all about knives and the

people who make and carry them. |

|

*************

Customs agents have not been allowing soldiers to return

home with any knife over 4" long in their checked baggage. Many soldiers

had to throw their Ka-Bars and other privately purchased knives in the

trash before they could board a plane home.

When I returned home from Iraq, I got around it by via

registered mail through the USPS.

I suspect that customs agents are enforcing their own policy

rather than US law when they make soldiers throw their knives in the

trash rather than allow them to bring them home in checked baggage.

**************** |

|

|

|

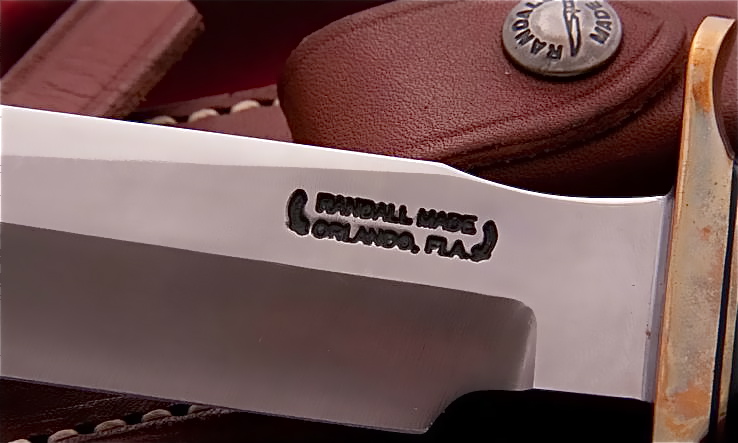

Randall Made Orlando Fla - Mark |

The original

Randall knife

creator W. D. or Bo

Randall died in December of 1989. The older Randall knives are worth

five to fifteen times their original value. They are an excellent

investment. Randall knives are not mass produced. Randall Knives are

considered true collectible pieces. Randall is renowned for making some

of the best caliber hand-made knives in the world.

Gary Randall, the present owner, took over from his

father, "Bo" Randall, in the mid 1970's and the shop remains so busy

that today it takes over four years to get a knife directly from them.

The famous Randall Made Knives are still 100% handmade by skilled

craftsman under the direction of Gary Randall. Continued dedication to

quality workmanship and design have made the Randalls and their knives

true "Legends in their own time".

A Few Notes About

Randall Blades: Almost all Randall blades are forged

on an anvil mounted on a section of log in their forging room. From

start to finish, all blade work is done in Randall's shop, including

heat treatment. The tool steel blades are made of Swedish Uddeholm

FB-01, a high carbon, oil hardened, fine grain steel. The stainless

steel is American 440B, an air hardened, stainless die steel. |

|

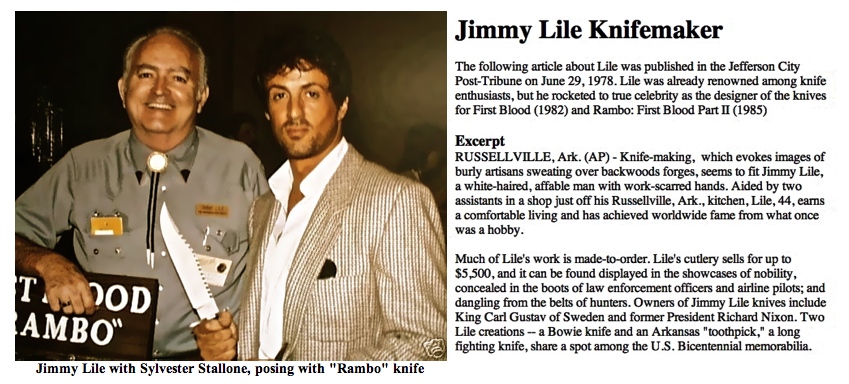

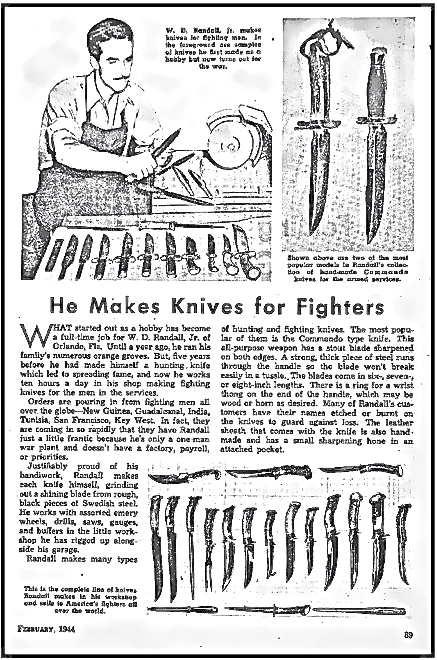

The Randall Story

In the late ‘30s, Florida citrus grower Walter Doane Randall, Jr. was

vacationing at his family cabin on Walloon Lake, in Michigan. He saw his

pal “Litch” Steinman scraping the hull of a boat with a Scagel knife.

Randall decided to make himself one like it. He did, and someone asked

to buy it. After this happened several times in succession, Randall

thought that it might be a good idea to produce these handcrafted works

of art on a regular basis. In 1938, he founded Randall Made Knives.

The deluge of publicity began in 1943, with a newspaper item that

syndicated press affiliation spread across the country and into foreign

lands where American GI’s read it. The fledgling company’s war effort

flourished, and before long, many Randall knives were in the hands of

troops on all fronts. Among the more noted owners were Maj. Richard

Bong, a leading fighter ace, and Lt. General James M. Gavin, who led the

82nd Airborne Division into Normandy on that crucial day in June of

1944. Col. Rex Applegate, an OSS trainer in close combat, wrote a little

manual on how to use the knife in battle, which happened more often than

some modern scribes would have one believe. Knives and bayonets were

especially effective in the Ranger attack on Axis positions at El

Guettar in North Africa, and during the long Allied march up the “boot”

of Italy. One correspondent told ‘Bo’ Randall that his Model 1 fighting

knife played a “significant” role in his being credited with 384 enemy

dead!

The basis for the new dive knife was a pair of military designs that Bo

had developed for the Marine Corps Equipment Board. These became the

Model 14 Attack (for infantry) and Model 15 Airman, for pilots. The

officers on the project never did much about it, and the Air Force,

although impressed, admitted that their budget for survival items was

too tight to buy such things. Nevertheless, both styles have been wildly

popular with servicemen in all branches of the armed forces, who somehow

found the money to buy them out of their own meager pay. |

|

|

|